Introduction to Home Appliance Technology

The evolution of home appliances has been significantly influenced by technological advancements over the past few decades. Modern home appliances, such as refrigerators, washing machines, and microwaves, have transformed from simple mechanical devices into sophisticated systems that offer enhanced functionality and efficiency. This transformation is largely attributed to the integration of automation and smart technologies, which have revolutionized the manufacturing processes and operational capabilities of these essential devices.

Traditionally, the production of home appliances involved manual labor and basic mechanical principles. However, with the onset of automation, manufacturers have adopted advanced robotics and computerized systems to facilitate higher precision, faster production times, and improved product quality. These smart manufacturing techniques not only streamline the assembly line but also reduce human error and lower production costs. As a result, consumers now benefit from high-quality appliances that are built to meet rigorous standards and provide dependable performance.

In addition to automation, the rise of the Internet of Things (IoT) is further changing the landscape of home appliance technology. Smart appliances capable of connecting to the internet can be remotely monitored and controlled via smartphones or other devices. These connected technologies enable homeowners to optimize energy efficiency, enhance convenience, and ensure optimal operation of various appliances. For instance, a smart thermostat can learn user preferences and adjust heating and cooling accordingly, leading to significant energy savings.

The role of software and artificial intelligence in home appliance technology cannot be understated. Manufacturers are now incorporating intelligent algorithms that can predict maintenance needs and enhance user experience through personalized settings. This shift toward technology-driven appliances is reshaping household dynamics, allowing for a more efficient and interconnected lifestyle. Overall, the advancements in home appliance technology illustrate a growing trend towards integrated, intelligent solutions that improve the functionality and efficiency of everyday life.

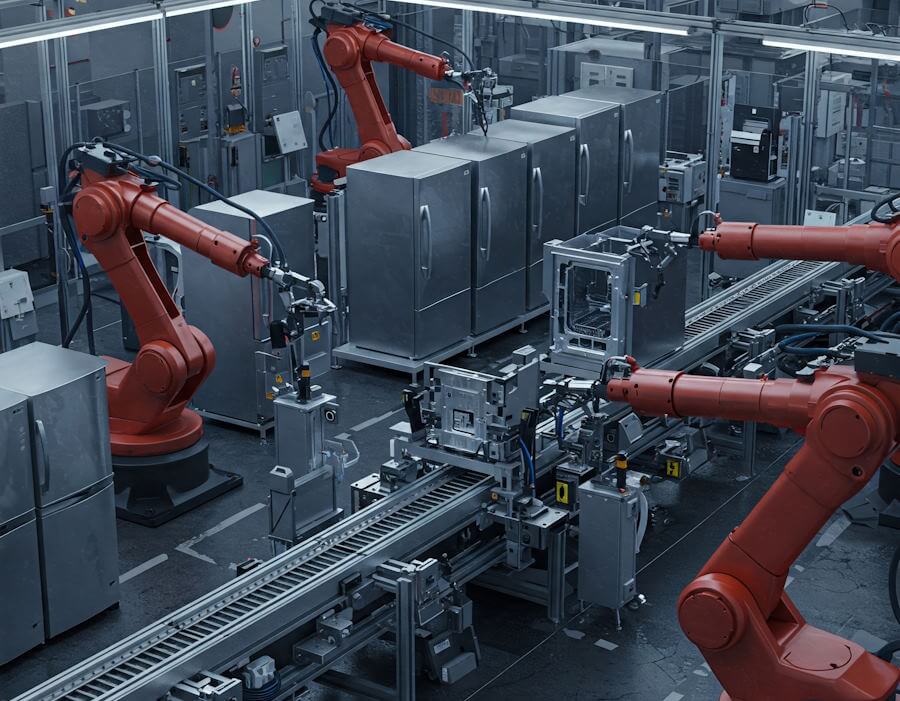

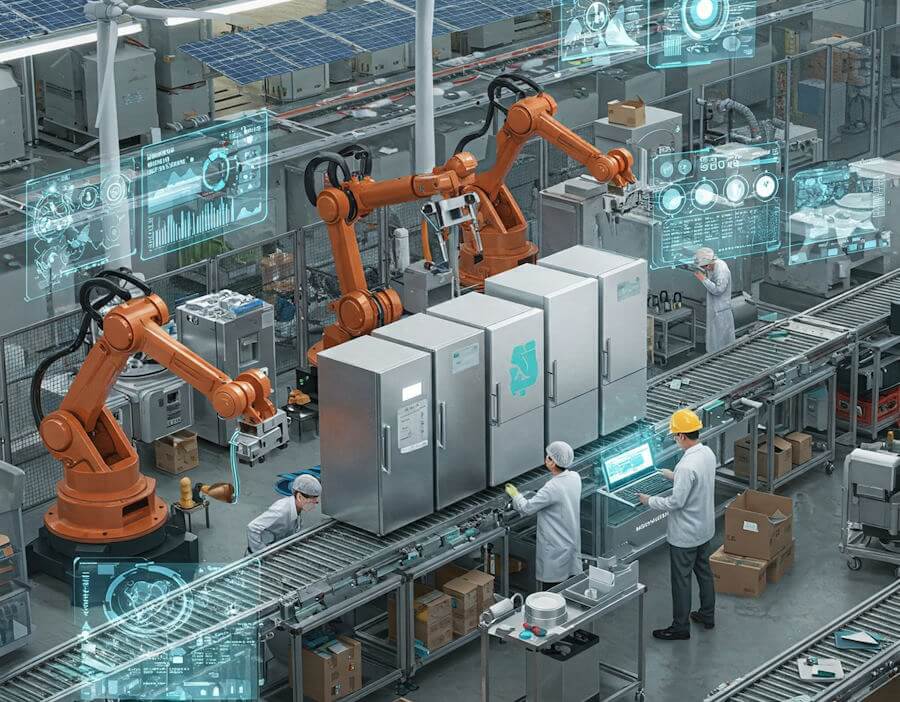

Automation in Manufacturing Processes

The advancement of automation in manufacturing processes has significantly transformed the production of home appliances, marking a pivotal shift from traditional methods to a more technologically driven framework. The incorporation of robotic systems and automated assembly lines plays a crucial role in increasing efficiency across various manufacturing plants. By implementing these automated solutions, companies are able to streamline their workflows, reduce production times, and ultimately deliver superior products to consumers.

One of the most notable benefits of automation is its impact on manufacturing costs. By utilizing robotic technology, companies can minimize labor expenses, as machines are often more efficient and can operate at a constant pace without the need for breaks or overtime. This reduction in labor costs can facilitate more competitive pricing for home appliances in the market. Moreover, automation helps to optimize resource utilization, leading to lower waste and better overall production efficiency. As a result, manufacturers are able to achieve economies of scale that were previously unattainable with manual processes.

Additionally, the integration of automated systems has proven to enhance product quality. Robots equipped with precision engineering capabilities can perform repetitive tasks with high accuracy, drastically reducing the likelihood of errors that are often associated with manual labor. This consistency ensures that each appliance produced meets stringent quality standards, thereby increasing customer satisfaction and bolstering brand reputation. Furthermore, the advanced feedback mechanisms in automated systems allow manufacturers to quickly identify defects or issues, facilitating faster corrective actions and ensuring continuous improvement in quality control.

In this context, the role of automation in the manufacturing of home appliances cannot be overstated. By leveraging modern technologies, manufacturers are not only improving operational efficiency but also enhancing the overall quality and reliability of the products they offer to the market. This ongoing evolution in manufacturing practices is setting new benchmarks for the industry, ultimately benefiting both manufacturers and consumers alike.

Integration of Smart Technology

The integration of smart technology into modern home appliances has transformed the way individuals interact with their daily tools. Smart appliances leverage the Internet of Things (IoT) and Artificial Intelligence (AI) to enhance functionality, efficiency, and user experience. With IoT, devices can connect to the internet, allowing for remote control and monitoring through smartphones or tablets, which has become a hallmark feature of contemporary home living.

One of the prime examples of this technological advancement is the smart refrigerator. These modern fridges are equipped with sensors and connectivity options that enable users to access information about their food inventory even when they are away from home. Many smart refrigerators can also suggest recipes based on the ingredients available inside, and some can automatically order groceries when supplies run low, making meal planning and grocery management more efficient.

Washing machines have also benefited significantly from the integration of smart technology. Today’s smart washers offer app-based controls, allowing users to start or pause washing cycles remotely. These machines are often programmed to learn the user’s washing habits and can optimize settings accordingly. Additionally, they may provide alerts when a cycle is complete or if maintenance is needed, thus enhancing user convenience and promoting appliance longevity.

Similarly, smart ovens equipped with AI capabilities can adjust cooking times and temperatures based on the type of food being prepared. These devices can pre-heat automatically upon receiving a command from a connected device, or even suggest cooking settings based on real-time recognition of the dish. This level of automation not only simplifies the cooking process but also helps in achieving better results in meal preparation.

Through the seamless integration of IoT and AI, modern home appliances demonstrate a commitment to improving household efficiency and user satisfaction. This smart technology not only streamlines tasks but also addresses users’ preferences, marking a significant evolution in the appliance industry.

Sustainability and Energy Efficiency

In recent years, the integration of technology into home appliance production has significantly advanced sustainability and energy efficiency. Manufacturers are increasingly prioritizing eco-friendly practices that not only reduce their environmental impact but also enhance the performance of their products. One of the most notable innovations in this area is the development of energy-efficient appliances that consume substantially less power compared to traditional models.

Technological advancements have enabled the design of appliances that incorporate smart features, allowing consumers to monitor and control energy usage remotely. For instance, smart thermostats and refrigerators can learn user behaviors and optimize their operational settings accordingly. This results in lower energy consumption without compromising convenience or performance. Additionally, many modern appliances now bear Energy Star ratings, which serve as a standard for energy efficiency and aid consumers in making informed purchasing decisions.

Moreover, manufacturers are exploring the use of sustainable materials in appliance production. The shift toward eco-friendly materials—such as recycled plastics, bamboo, and other biodegradable resources—has been notable in recent years. By utilizing these materials, producers are not only reducing waste but also contributing to a circular economy where products are designed for reuse and recyclability. This innovative approach not only minimizes environmental impact during the production phase but also enhances the overall sustainability of home appliances throughout their lifecycle.

Furthermore, as technology continues to evolve, there is growing potential for collaborative efforts between manufacturers and tech companies to further enhance sustainability. Research and development initiatives focused on low-impact production techniques and the reduction of carbon footprints are becoming increasingly common. Collectively, these trends are shaping a new era in home appliance production, whereby sustainability and energy efficiency are integral to both innovation and market competitiveness.

Customization and Personalization Features

In recent years, the advancement of technology has markedly influenced the production of home appliances, particularly in terms of customization and personalization features. As consumer preferences evolve, manufacturers are increasingly leveraging technology to design appliances that cater to individual needs and tastes. The rise of data analytics and design software has revolutionized how companies approach product development, enabling a more tailored customer experience.

One of the significant ways technology is enhancing customization is through the collection and analysis of consumer data. By utilizing big data, manufacturers can gain insights into consumer behavior, preferences, and emerging trends. This information empowers companies to develop appliances that align with specific user requirements, allowing for a more personalized selection process. For example, smart home technology enables appliances to adapt to user habits, enhancing convenience and efficiency. An appliance that learns from its owner’s usage patterns not only provides greater ease of use but also contributes to energy savings.

Additionally, sophisticated design software is facilitating the creation of customizable features in appliances. This technology permits manufacturers to offer a range of options, such as colors, finishes, and functionalities, which cater to diverse consumer preferences. For instance, a refrigerator may allow users to select different shelving configurations or temperature zones to optimize storage based on personal requirements. By integrating personalization into the design process, companies are not only enhancing user satisfaction but also fostering brand loyalty.

Moreover, with the rise of 3D printing technology, the possibility of creating bespoke appliances has become more feasible. This innovation enables manufacturers to produce unique components and accessories that meet specific consumer demands. Ultimately, the combination of data analytics, design software, and advanced manufacturing techniques signifies a shift towards a more consumer-centric approach in home appliance production, underscoring the critical role of technology in fostering greater customization and personalization.

Impact of Consumer Feedback and Data Analysis

In the rapidly evolving landscape of home appliance production, technology has emerged as a transformative force in how manufacturers engage with consumer feedback. The integration of advanced data analytics allows companies to collect extensive information regarding user preferences, experiences, and expectations for their products. By employing online surveys, social media monitoring, and direct customer interactions, manufacturers can gain valuable insights into consumer sentiment, which is crucial for enhancing product design and functionality.

Moreover, the utilization of data analysis tools assists companies in identifying trends and patterns within the feedback data. This systematic approach enables manufacturers to understand what features resonate most with consumers and where there may be shortcomings in existing products. For instance, if a significant number of users express dissatisfaction with a particular appliance’s energy efficiency, manufacturers can prioritize improvements in that area during the next product development cycle. By aligning their offerings with real consumer needs and preferences, manufacturers can enhance customer satisfaction and loyalty.

Importantly, data analysis also plays a significant role in shaping effective marketing strategies. Understanding consumer feedback enables brands to develop targeted marketing campaigns that highlight product attributes most valued by potential buyers. Additionally, this informed approach can enhance communication strategies, ensuring that messaging resonates with the target audience. Through responsive adaptations based on consumer insights, home appliance manufacturers can significantly improve their competitive edge in the market. In a marketplace increasingly dominated by tech-savvy consumers, leveraging data-driven decisions is vital for success. Ultimately, the enhanced communication between manufacturers and consumers fosters an ecosystem where innovation aligns with user expectations, leading to better appliance designs.

Challenges in Modern Home Appliance Production

The landscape of home appliance production is undergoing significant transformation due to the rapid evolution of technology. Manufacturers face the challenge of continuously adapting to new advancements that can enhance energy efficiency, user experience, and overall functionality. As technology progresses at an unprecedented pace, the pressure is on home appliance producers to innovate continually while ensuring that consumers benefit from the latest features and improvements. Failing to keep up can render products obsolete in a matter of months, creating a daunting environment for manufacturers.

In addition to technological advancements, the home appliance sector is characterized by increasing competition. New entrants continually enter the market, often introducing innovative products at competitive prices. Established brands must navigate this surge of competition by not only differentiating their offerings but also streamlining production processes to avoid rising costs. Manufacturers are compelled to balance the need for innovation with the financial realities of a crowded market—an endeavor that requires strategic planning and a keen understanding of consumer demands.

Cybersecurity concerns also present a significant challenge that modern home appliance manufacturers must contend with. As appliances become smarter and more interconnected, the risk of cyber threats escalates. Households increasingly depend on smart appliances for various tasks, making it crucial for manufacturers to implement robust security measures. Any breach could lead to far-reaching consequences, not only compromising user data but also damaging brand reputation. For manufacturers, ensuring that their products are secure against potential attacks adds an additional layer of complexity to the production process.

Lastly, maintaining product relevance in a fast-paced market requires manufacturers to continuously engage in market research and consumer feedback assessments. Understanding shifting preferences is vital to creating appliances that not only meet current demands but also anticipate future trends. Through proactive adaptation to these challenges, manufacturers can ensure a sustainable and competitive presence in the dynamic landscape of home appliance production.

Future Trends in Home Appliance Technology

The landscape of home appliance technology is poised for significant transformation, driven by advancements that prioritize sustainability, automation, and innovative design. One of the most notable trends on the horizon is the increased integration of renewable energy sources. As energy efficiency becomes paramount, future appliances are likely to harness solar power or other green technologies, reducing reliance on fossil fuels. This shift is not only a reaction to environmental concerns but also a proactive approach to reducing energy costs for consumers.

Another prevailing trend is the rise of fully automated households, commonly referred to as smart homes. With the proliferation of the Internet of Things (IoT), appliances will become increasingly interconnected, allowing for seamless communication between devices. Imagine a refrigerator that can order groceries based on its inventory or a washing machine that can schedule a wash cycle based on energy pricing. This level of automation promises to enhance convenience, optimize energy usage, and provide users with greater control over their living environments.

In addition to these advancements, we can anticipate potential innovations in materials and design that will redefine home appliances. Smart materials that adapt to user behavior or environmental conditions and ergonomic designs will likely play a crucial role in shaping future products. The use of sustainable materials that are durable and aesthetically pleasing will align with the growing consumer demand for eco-friendly solutions. Furthermore, advancements in artificial intelligence will lead to appliances that learn from usage patterns, thereby improving their efficiency and enhancing user experience.

In conclusion, the future of home appliance technology is marked by a commitment to sustainability, automation, and innovative designs. As consumers increasingly prioritize energy efficiency and convenience, manufacturers are likely to respond with forward-thinking solutions that harness the power of renewable energy and smart technology.

Conclusion: The Symphony of Technology and Home Appliances

In today’s rapidly evolving landscape, technology plays a pivotal role in the production and advancement of home appliances. Throughout this discussion, we have explored how technological innovations have transformed traditional appliances into smart devices that not only enhance efficiency but also cater to the diverse needs of modern consumers. These advancements include connectivity features, energy efficiency, and user-friendly interfaces that make everyday tasks more manageable.

Moreover, the integration of cutting-edge technology in home appliance production has fostered a new era of consumer-driven designs. Manufacturers are increasingly investing in research and development to create products that resonate with user preferences and lifestyles. This convergence of consumer insight and technological capability ensures that appliances are not merely functional but also intuitive and adaptable. As a result, consumers can enjoy a streamlined experience that simplifies their daily routines.

Sustainability has emerged as a significant factor in the production of home appliances. In response to increasing environmental concerns, manufacturers are turning to innovative materials and processes that minimize waste and energy consumption. This shift towards greener solutions not only meets regulatory requirements but also aligns with the values of eco-conscious consumers. The emphasis on sustainability is, therefore, not only a business strategy but a critical component of responsible production practices that ensure the longevity of both the industry and the planet.

The future of home appliances lies in the harmonious balance of technological advancement, consumer needs, and sustainability initiatives. As manufacturers continue to harness the power of technology, the industry is poised for growth that prioritizes innovation while remaining sensitive to environmental impacts and consumer demands. This symbiotic relationship will define the next generation of home appliances, ensuring they contribute positively to our lives and the world around us.