Energy efficiency refers to the use of technology and practices that consume less energy while delivering the same level of performance or service. This concept has gained paramount importance in recent years, particularly with increasing concerns over climate change and the rising costs of energy. In the context of home appliances, energy efficiency plays a crucial role in achieving a sustainable lifestyle. By utilizing energy-efficient appliances, households can significantly reduce their energy consumption and, subsequently, lower their utility bills.

The growing significance of energy efficiency in home appliance manufacturing is driven by several factors. Firstly, the environmental impact of energy consumption is a pressing global issue. According to various studies, a substantial portion of greenhouse gas emissions can be attributed to household energy use. Therefore, improving the energy efficiency of home appliances contributes directly to reducing these emissions, thereby assisting in the fight against climate change.

Moreover, consumers are becoming increasingly conscious of their energy consumption patterns. There is a rising demand for appliances that not only perform efficiently but also offer long-term savings. Manufacturers are responding to this trend by integrating energy-efficient technologies into their products. This transition is not merely a trend but a necessary shift to meet regulatory standards and consumer expectations.

Additionally, energy-efficient appliances often feature innovative designs and advanced technologies that enhance user experience while promoting environmental responsibility. Energy Star certifications, for instance, have become a benchmark for consumers looking to purchase appliances with reduced energy consumption.

Overall, understanding energy efficiency is essential for both producers and consumers in the home appliance sector. As the market continues to evolve, the focus on energy-efficient solutions will be critical in shaping the future of home appliance manufacturing, making it an integral component of sustainable development.

The Role of Home Appliance Manufacturers

Home appliance manufacturers hold a critical position in the promotion of energy efficiency within the industry. Their influence extends across various stages, from the initial design phase to the final production processes, significantly affecting the energy consumption of appliances. By making informed design choices, manufacturers can create products that consume less energy while still meeting consumer demands for performance and reliability.

One primary aspect where manufacturers can enhance energy efficiency is through the selection of materials. The type of materials used in appliances can determine not only the longevity of the product but also its energy consumption. For instance, incorporating insulation materials that minimize energy loss can lead to reduced operational energy requirements. Additionally, manufacturers focusing on sustainable materials can further contribute to an eco-friendly production model that adheres to environmental standards.

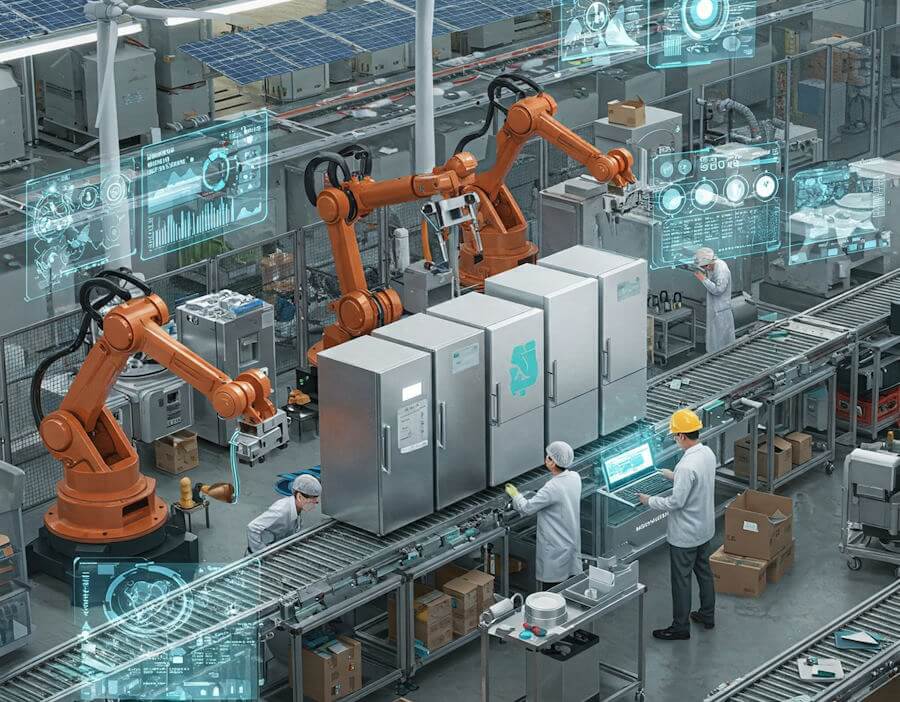

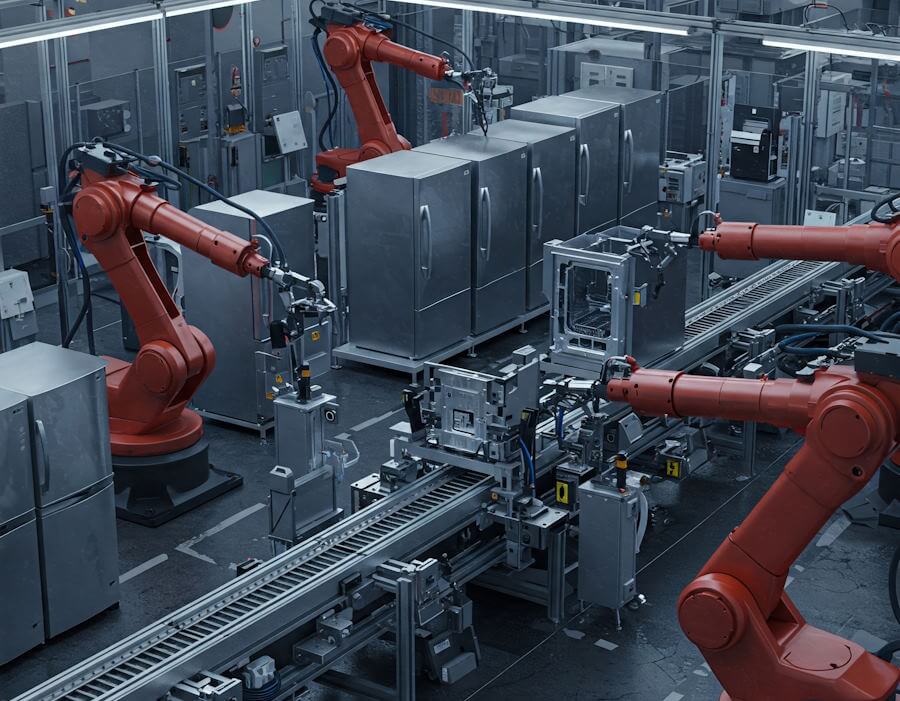

Moreover, advanced production processes enable manufacturers to optimize energy use during the manufacturing stage itself. Implementing state-of-the-art technologies can streamline processes, reduce waste, and lower energy expenditures. Additionally, manufacturers can transition to renewable energy sources in their production facilities, which not only diminishes their carbon footprint but can also have cost-saving implications in the long run.

Furthermore, manufacturers have the potential to influence consumer behavior by highlighting the energy efficiency of their products. As consumers become increasingly aware of energy consumption, they often seek appliances that are certified for energy efficiency. By prominently showcasing energy labels and certifications, home appliance manufacturers can not only improve their market competitiveness but also educate consumers about the importance of energy-efficient choices.

In conclusion, home appliance manufacturers play a pivotal role in promoting energy efficiency through strategic design, sustainable material selection, and innovative production processes. Their efforts contribute significantly to the broader sustainability goals of reducing energy consumption and minimizing environmental impact.

Current Standards and Regulations

In recent years, energy efficiency has emerged as a crucial focus in the manufacturing of home appliances. Various standards and regulations have been implemented to ensure that appliances meet specific energy efficiency benchmarks. These guidelines are established at both governmental and international levels, driving manufacturers to innovate and enhance their products. One prominent initiative in this regard is the ENERGY STAR program, which was introduced by the United States Environmental Protection Agency (EPA) in 1992. This program labels products that significantly exceed minimum efficiency requirements, encouraging consumers to make more informed choices when purchasing home appliances.

Moreover, the European Union has established its own framework of regulations that includes the Energy Labeling Directive and Ecodesign Directive. These measures aim to improve the environmental performance of products throughout their entire lifecycle. Under these directives, appliances are graded based on their energy consumption, providing consumers with straightforward information about the energy efficiency of various models. As a result, manufacturers are constantly striving to design products that not only meet but exceed these regulations, fostering continuous advancements in technology and energy management.

In addition to these voluntary programs, mandatory regulations have been set in various jurisdictions to ensure compliance with energy efficiency standards. For instance, in the United States, federal guidelines require appliances to meet specific energy use criteria. Similarly, many countries have adopted similar laws to promote sustainable practices within the manufacturing sector. These standards effectively compel manufacturers to invest in research and development aimed at improving the energy performance of home appliances, thus aligning with global efforts to reduce energy consumption and greenhouse gas emissions.

Overall, the synergy between governmental regulations and voluntary certifications like ENERGY STAR plays a significant role in pushing manufacturers towards increased energy efficiency. This collective effort not only benefits consumers through reduced energy costs but also contributes to broader environmental sustainability goals.

Technological Innovations in Energy Efficiency

In the realm of home appliance manufacturing, technological innovations have significantly contributed to enhancing energy efficiency. These advancements have not only improved the functionality of appliances but have also aligned with the growing demand for sustainable living solutions. One of the most notable developments is the emergence of smart appliances, which integrate advanced technology to optimize energy usage. These devices can connect to the internet and allow users to monitor and control their energy consumption remotely, leading to more efficient operation tailored to individual needs.

Smart appliances often come equipped with energy-saving modes that automatically adjust their performance according to usage patterns, such as reducing power consumption during peak hours or adapting to the user’s routine. For instance, a smart refrigerator can regulate its cooling efficiency based on the frequency of door openings or the volume of food stored. This ability to self-regulate not only conserves energy but also prolongs the lifespan of the appliance, showcasing a significant leap in design and engineering.

Moreover, the utilization of advanced materials in appliance manufacturing plays a crucial role in enhancing energy efficiency. Manufacturers are increasingly adopting lightweight, insulating materials that minimize energy loss. These materials improve the thermal performance of appliances, ensuring they operate effectively while consuming less energy. Additionally, advancements in compressor technologies and motor efficiency contribute to reducing energy consumption in devices such as washing machines and air conditioners.

Significantly, these technological advancements in home appliance manufacturing exemplify a collective effort toward energy efficiency. The integration of smart technology, energy-saving modes, and innovative materials not only enhances appliance performance but also promotes environmental sustainability. As these innovations continue to evolve, consumers can expect even greater energy efficiency in their home appliances, paving the way for a greener future.

Consumer Expectations and Market Trends

In the contemporary marketplace, energy efficiency in home appliances has ascended to a position of paramount importance among consumers. As awareness surrounding environmental issues grows, customers increasingly prioritize energy-efficient products that not only reduce utility bills but also minimize their carbon footprint. According to recent studies, a significant majority of consumers are now willing to invest more in appliances that promise greater energy efficiency. This shift reflects an evolving mindset where sustainability and cost-effectiveness are intertwined.

Market trends indicate that consumers are actively seeking labels and certifications that validate the energy efficiency of appliances. The Energy Star label, for instance, has gained substantial traction among buyers, serving as a trusted indicator of minimal energy consumption without sacrificing performance. This growing expectation compels manufacturers to focus on innovation and transparency to meet consumer demand. As a result, brands are integrating advanced technologies, such as smart thermostats and energy-monitoring systems, into their appliances, enhancing usability while promoting conservation.

The competitive landscape has shifted significantly as well. To remain relevant, manufacturers must adapt to these consumer preferences by committing to energy-efficient solutions in their product lines. The introduction of eco-friendly materials and sustainable manufacturing practices are becoming key differentiators for brands. Additionally, companies are increasingly engaging in marketing campaigns that showcase their commitment to sustainability and energy conservation, which resonates positively with environmentally conscious consumers.

In essence, the convergence of consumer expectations and market trends reflects a broader societal shift towards a more sustainable future. Home appliance manufacturers that embrace these values are more likely to thrive in an increasingly competitive environment. By prioritizing energy efficiency, brands not only meet consumer needs but also contribute to a collective effort towards environmental stewardship.

Benefits of Energy-Efficient Appliances

The adoption of energy-efficient appliances has gained significant attention in recent years, largely due to their multifaceted benefits. One of the most compelling advantages is the notable reduction in energy costs. Energy-efficient appliances are designed to consume less electricity, which directly translates to lower utility bills. For instance, appliances that are rated highly for energy efficiency use innovative technology to decrease energy consumption, resulting in substantial savings over time. These financial benefits can significantly alleviate the burden of monthly expenses, making them an attractive investment for consumers.

Moreover, the environmental impact of energy-efficient appliances cannot be overlooked. By utilizing less energy, these appliances contribute to decreased greenhouse gas emissions, thus supporting global efforts to combat climate change. As households shift towards more sustainable energy consumption, they help reduce the demand for fossil fuels, which in turn minimizes the overall carbon footprint associated with energy production. This shift not only benefits individual households but also has a positive cascading effect on the environment as a whole, promoting a sustainable future.

In addition to cost savings and environmental benefits, energy-efficient appliances often outperform their conventional counterparts. These appliances are typically designed with advanced technology that enhances their functionality and effectiveness. For example, energy-efficient refrigerators maintain optimal cooling while using less energy, and washing machines ensure thorough cleaning with minimal resource use. Furthermore, consumers may discover potential tax credits or rebates when purchasing energy-efficient products, providing an additional financial incentive to choose them. Such programs, often implemented by governments to encourage energy-saving practices, can make the initial investment in energy-efficient appliances even more appealing.

Challenges in Achieving Energy Efficiency

Achieving energy efficiency in home appliance manufacturing presents several significant challenges for manufacturers. One primary obstacle is the cost associated with developing and integrating advanced technologies designed to improve efficiency. Many manufacturers face a dilemma: investing in innovative materials and technologies can lead to higher initial production costs. This could result in increased retail prices, which may deter consumers who are not yet fully convinced of the long-term savings associated with energy-efficient appliances. Manufacturers must conduct a careful analysis of their pricing strategies to ensure that the improvements in energy efficiency convey tangible value to consumers.

Another challenge arises from the complexity of integrating new technologies into existing manufacturing processes. Manufacturers often face difficulties related to upgrading machinery, training staff, and ensuring that new systems work seamlessly with established workflows. The introduction of energy-efficient components often requires a rethinking of the entire design process, which can lead to delays in production and increased operational costs. This process can be daunting, particularly for smaller manufacturers who may lack the resources to adapt swiftly to new standards.

The balance between performance and energy efficiency is also a critical consideration. Consumers typically demand appliances that not only save energy but also deliver high performance and reliability. Manufacturers must navigate this balance carefully, ensuring that energy-efficient models do not compromise on functionality. For instance, laundry machines that consume less water must still effectively clean clothes, and refrigerators that use less electricity must maintain the same cooling performance. Striking this balance is essential in fostering consumer trust and satisfaction with energy-efficient products.

In conclusion, the path to achieving energy efficiency in home appliance manufacturing is fraught with challenges that require strategic planning and investment. Manufacturers must address cost, technology integration, and performance metrics to create products that meet consumer expectations while also contributing positively to sustainability goals.

The Future of Home Appliance Manufacturing

The home appliance manufacturing industry is poised for significant transformation as energy efficiency becomes increasingly paramount. With the global push toward sustainability, manufacturers are recognizing the need to meet stringent environmental regulations and consumer demand for eco-friendly products. As energy consumption remains a critical concern, future innovations are expected to focus heavily on reducing energy usage without compromising functionality.

Technological advancements in materials and design will likely play a crucial role in the next generation of appliances. For instance, the integration of smart technology into home appliances allows for improved energy management. Devices equipped with artificial intelligence (AI) can learn user habits and optimize energy use accordingly. Such innovations not only enhance energy efficiency but also cater to the growing consumer desire for smart home solutions that provide convenience and automation.

As sustainability becomes ingrained in consumer behavior, manufacturers will need to adapt their strategies accordingly. Eco-labeling, which provides transparent information regarding energy consumption, will gain prominence. Consumers are increasingly favoring products that are not only energy-efficient but also produced sustainably. This shift in purchasing behavior is likely to incite manufacturers to prioritize the life cycle of products, selecting materials that are sustainable and promoting recycling initiatives.

Additionally, collaboration among stakeholders—including governments, manufacturers, and consumers—will be essential for driving advancements in energy efficiency. Policy frameworks that incentivize energy-efficient manufacturing practices can foster a more sustainable marketplace. These changes reflect a broader commitment to environmental stewardship and energy conservation, forming a pathway for a resilient and dynamic future in home appliance manufacturing.

Conclusion and Call to Action

In recent years, energy efficiency has emerged as a pivotal factor in the manufacturing of home appliances. As the world grapples with the challenges of climate change and resource conservation, manufacturers are increasingly prioritizing energy-efficient technologies. This trend is not just beneficial for the environment; it also provides significant cost savings for consumers in the long run. The features found in modern energy-efficient appliances, such as reduced energy consumption and advanced technologies, underscore the industry’s commitment to sustainability.

Investing in energy-efficient home appliances can lead to considerable reductions in electricity usage, contributing to a smaller carbon footprint. This not only aids in fighting global warming but also enhances the overall efficiency of households. As consumers, choosing products that meet or exceed energy efficiency standards is crucial. Such choices encourage manufacturers to innovate and maintain focus on developing eco-friendly solutions. It is essential to look for energy ratings when purchasing appliances, as these ratings indicate the effectiveness of the product in saving energy.

Moreover, supporting regulations that advocate for energy efficiency in the manufacturing sector can foster a healthier environment for generations to come. Policymakers play an integral role in shaping standards that drive the industry towards more sustainable practices. As a community, increased advocacy for these regulatory measures can motivate the market towards greener initiatives. Therefore, it is vital for consumers to remain informed about energy efficiency practices and to actively engage in discussions regarding the necessity of robust environmental regulations in the appliance manufacturing sector.

In summary, prioritizing energy efficiency in our choices as consumers, alongside supporting legislative efforts, is necessary for promoting a sustainable future in home appliance manufacturing. By taking these actions, we collectively contribute to a greener planet and a more responsible manufacturing industry.