Global supply chains represent a complex network of producers, suppliers, and logistics partners interconnected across various countries. Their primary purpose is to facilitate the movement of goods and services, maximizing efficiency while minimizing operational costs. In contemporary economies, these supply chains are vital, especially for sectors such as home appliance production, where components are frequently manufactured in different regions of the world before being assembled into a final product.

A global supply chain operates through several stages, beginning with raw material extraction, followed by manufacturing, assembly, and distribution. Each step may involve different geographical locations, taking advantage of regional strengths, such as cost-effective labor or access to unique materials. This international collaboration enables home appliance manufacturers to optimize their processes, capitalize on comparative advantages, and ultimately deliver superior products at competitive prices.

The significance of global supply chains cannot be overstated. They play an essential role in enhancing product availability, allowing companies to respond dynamically to consumer demand and market fluctuations. By leveraging diverse manufacturing locations, companies can maintain a steady supply of home appliances while ensuring the timely introduction of new innovations. Additionally, these networks contribute to resilience against external shocks, such as natural disasters or geopolitical tensions, by diversifying sourcing options and minimizing dependencies on specific regions.

As businesses continue to navigate the challenges of globalization and evolving market demands, understanding the intricacies of global supply chains becomes increasingly important. The interplay between different manufacturers and suppliers not only shapes the production landscape of home appliances but also drives the overall efficiency and sustainability of the economy. In this dynamic environment, effectively managing global supply chains will remain a critical factor for success.

The Home Appliance Industry: An Overview

The home appliance industry plays a crucial role in the global market, encompassing a vast array of products used for domestic settings. This sector includes various appliances, such as refrigerators, washing machines, microwaves, and dishwashers, all designed to enhance convenience and efficiency in household tasks. As of 2023, the home appliance market is valued at over $500 billion, demonstrating significant growth driven by advancements in technology and changing consumer preferences.

Recent trends indicate a shift towards smart technology, with an increasing number of consumers seeking connected appliances that integrate seamlessly into their daily lives. Manufacturers are responding by investing in research and development to innovate smart features, energy efficiency, and user-friendly designs. The demand for sustainable appliances has also surged, prompting companies to explore eco-friendly materials and energy-saving technologies.

Major players in the home appliance industry include well-established brands such as Whirlpool, Bosch, and LG, alongside emerging competitors that focus on niche markets or innovative products. These companies not only compete on price but also on the basis of technological innovation and customer service. Collaborations and partnerships are becoming more common, as firms aim to enhance their product offerings and market reach through shared knowledge and resources.

Additionally, consumer demands are evolving, with a growing emphasis on personalized solutions and customization. This is altering the production and distribution processes across the industry. As the need for global supply chains intensifies, manufacturers must navigate numerous challenges, including logistics, quality control, and regulatory compliance, which highlights the critical role these supply networks play within the home appliance sector.

Key Components of Global Supply Chains in Home Appliances

The production of home appliances relies on a complex network of global supply chains, characterized by several critical components that work together to ensure efficiency and effectiveness. Understanding these elements is essential for analyzing how they impact the overall production process.

First, raw material sourcing is a vital component, as it provides the necessary inputs for home appliance manufacturing. Manufacturers often depend on global suppliers for metals, plastics, and electronic components, which can vary significantly in availability and cost. This reliance on international suppliers introduces a level of vulnerability, as geopolitical tensions or natural disasters can disrupt the flow of materials. Thus, managing risks associated with raw material sourcing is crucial for maintaining production continuity.

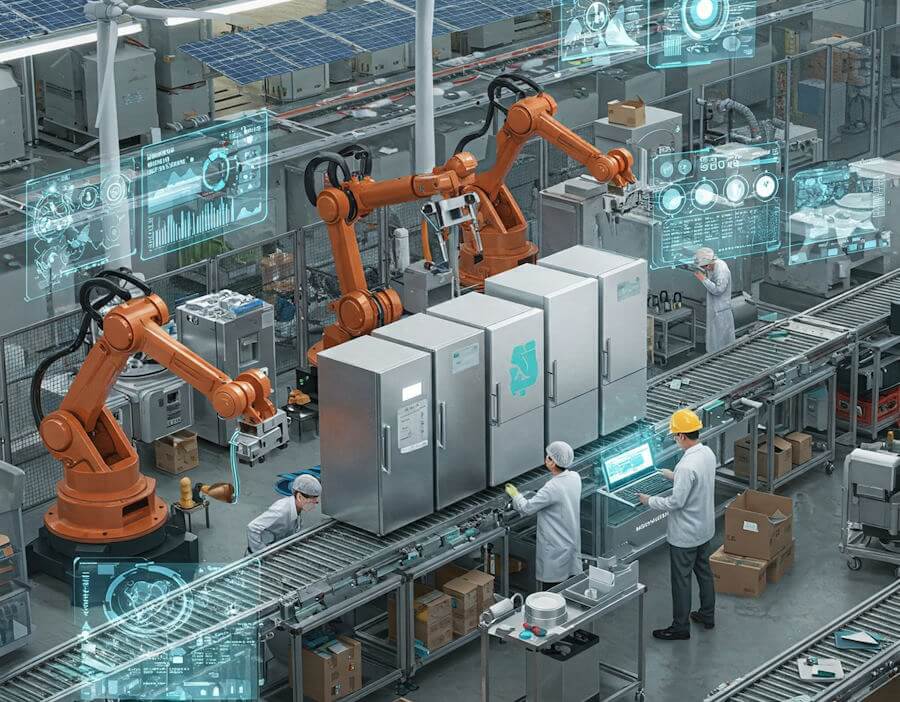

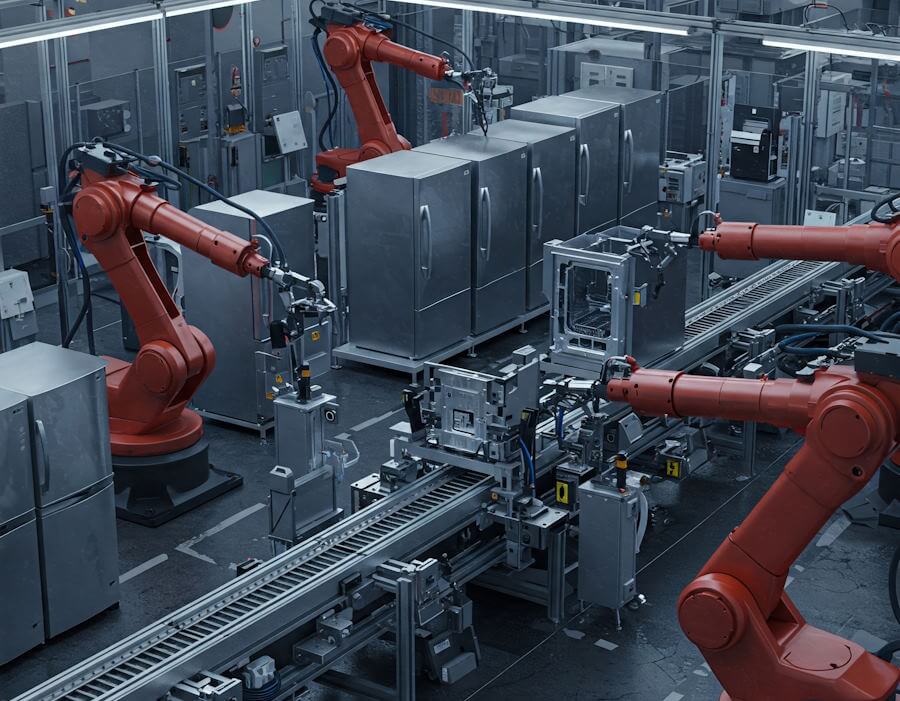

Second, the manufacturing processes themselves play a central role in the supply chain. Many home appliances are produced in specialized plants located in different countries, allowing firms to capitalize on comparative advantages such as lower labor costs or advanced technology. Each stage of manufacturing, from assembly to quality control, impacts not only the final product’s quality but also its overall cost. Moreover, as manufacturers increasingly adopt automation and smart technologies, the efficiency of these processes is continually evolving, further influencing production outcomes.

Logistics and distribution networks are also key components that enforce the interconnectedness of global supply chains. Efficient transportation systems, from shipping routes to warehousing facilities, are imperative for timely delivery of raw materials and finished goods. Delays in these logistics systems can lead to production bottlenecks, affecting the availability of home appliances in markets worldwide. Thus, orchestration of logistics is intrinsically linked to the effectiveness of supply chain management.

In conclusion, each component of the global supply chain, from raw material sourcing to logistics, plays a significant role in affecting the production of home appliances. Understanding these interconnected elements is critical for manufacturers striving to optimize their operations in a dynamic and increasingly interdependent global market.

Benefits of Global Supply Chains for Home Appliance Manufacturers

The integration of global supply chains has profoundly influenced home appliance production, offering several privileges to manufacturers. One of the primary benefits of global supply chains is the significant cost reduction achieved through outsourcing. By sourcing components and labor from countries with lower manufacturing costs, home appliance manufacturers can decrease overall production expenses. For instance, companies like Whirlpool have successfully outsourced certain production phases to countries such as Mexico and China, allowing them to maximize profitability while maintaining product quality.

Additionally, global supply chains provide manufacturers with access to a broader market for raw materials and skilled labor. This geographic diversity enables companies to obtain materials that may not be available domestically, ensuring the use of the best quality inputs in their products. For example, many appliance manufacturers utilize stainless steel sourced from specialty suppliers in different parts of the world, enhancing both the durability and aesthetics of their offerings.

The skilled labor advantage is another significant factor. Certain regions specialize in specific manufacturing competencies, giving home appliance producers access to a workforce that is not only well-trained but also experienced in producing high-demand products. This access helps manufacturers to innovate and improve their product lines continually, as seen in the case of Samsung, which leverages skilled labor in South Korea to design cutting-edge features in its appliances.

Moreover, a well-organized global supply chain enhances competitive positioning. By streamlining production and distribution across various regions, home appliance manufacturers can respond quickly to market demands, adjusting supply levels and production speeds as needed. This agility allows companies to stay ahead of competitors who might rely solely on local supply chains, thus reinforcing their market presence and ensuring sustained growth.

Challenges Faced by Home Appliance Producers in Global Supply Chains

Home appliance producers encounter a myriad of challenges within the complexities of global supply chains. One significant issue arises from supply chain disruptions, which can be triggered by geopolitical tensions, natural disasters, and unforeseen global events such as the COVID-19 pandemic. For example, trade disputes between countries may lead to increased tariffs and regulatory barriers, creating challenges for manufacturers seeking to import raw materials or components. Similarly, natural disasters, such as earthquakes or floods, can halt production in affected regions, thereby causing delays and increasing overall costs.

The ongoing impacts of the COVID-19 pandemic have further underscored vulnerabilities within global supply chains. Many manufacturers experienced supply shortages and delays as lockdowns and health protocols disrupted logistics networks. The resulting imbalance between supply and demand compounded existing challenges, forcing producers to rethink their procurement strategies and adapt to rapid market fluctuations. As a result, maintaining a stable supply chain has become increasingly difficult for home appliance companies.

In addition to physical disruptions, home appliance producers must also navigate the complexities of quality control and compliance with local regulations. Ensuring that products meet various international standards can be challenging, particularly when components are sourced from multiple countries with differing quality assurance protocols. Failure to comply with local regulations can lead to significant legal repercussions, including fines and restrictions on distribution. Consequently, manufacturers are compelled to invest in robust quality control measures and compliance strategies to mitigate risks associated with the international supply chain.

Overall, the challenges faced by home appliance producers in global supply chains highlight the need for adaptability and resilience in an ever-changing marketplace. By understanding and addressing these obstacles, companies can position themselves for enhanced competitiveness and sustainability in the future.

Sustainability and Ethical Considerations in the Supply Chain

In recent years, sustainability and ethical considerations have emerged as critical focal points within global supply chains, particularly in the home appliance sector. As consumers become more environmentally conscious, there is an increasing demand for sustainable sourcing and ethical manufacturing practices. This shift not only reflects a change in consumer preferences but also encourages companies to adopt more responsible operational strategies.

The home appliance industry, characterized by complex supply chains that often span multiple countries, faces unique challenges in promoting sustainability. Companies are now pressed to ensure that materials are sourced responsibly, minimizing environmental impact at every step of production. This includes utilizing renewable resources, reducing energy consumption during manufacturing, and implementing effective waste management practices. Furthermore, transparency in sourcing materials has become paramount, enabling consumers to make informed choices about the appliances they purchase.

Consumers have amplified their expectations for ethical practices, compelling manufacturers to evaluate their supply chains rigorously. This scrutiny often extends to labor practices, where companies must ensure fair treatment of workers throughout the supply chain. This includes adhering to ethical labor standards, minimizing exploitation, and promoting worker safety. Stakeholders, including investors, regulatory bodies, and advocacy groups, increasingly monitor corporate adherence to these principles.

Moreover, the role of technology in enhancing sustainability cannot be overlooked. Innovations such as blockchain can improve traceability and transparency, allowing consumers to verify the origins of the materials used in their appliances. This technological advancement not only builds trust but also empowers consumers to support brands that prioritize ethical and sustainable practices.

As the demand for sustainability and ethics continues to grow, the home appliance industry must adapt to these changes, embracing a holistic approach that integrates responsible sourcing, ethical labor practices, and technological advancements. Ultimately, a commitment to these principles is likely to foster a more resilient and sustainable supply chain.

Technological Innovations Impacting Supply Chains

The landscape of global supply chains in the home appliance industry has experienced a significant transformation due to technological advancements. Innovations such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain technology have emerged as key drivers reshaping the management and efficiency of these supply chains. Each of these technologies plays a critical role in enhancing production capabilities and ensuring a seamless flow of goods from manufacturers to consumers.

The IoT has revolutionized supply chain management by enabling real-time data tracking and monitoring of appliances during production and distribution. Sensors embedded in production equipment and shipments gather valuable data that can be analyzed to optimize manufacturing processes and inventory management. This connectivity allows for responsive adjustments to be made as conditions change, thereby minimizing delays and improving overall production efficiency within the supply chain.

Similarly, artificial intelligence has proven to be instrumental in enhancing decision-making processes across the supply chain. With the ability to analyze large sets of data, AI algorithms can forecast demand trends, optimize inventory levels, and streamline logistics operations. This predictive capability not only reduces wastage but also improves customer satisfaction by ensuring the timely availability of appliances in the market.

Blockchain technology further strengthens the transparency and accountability of global supply chains. By providing an immutable ledger of transactions, it enables stakeholders to trace the origin and journey of products throughout the supply chain. This traceability enhances trust among consumers and can also mitigate risks related to counterfeiting and product recalls, which is critical in the highly competitive home appliance sector.

Overall, these technological innovations are integral in creating more efficient, transparent, and responsive global supply chains, leading to significant improvements in the production and distribution of home appliances. As the industry continues to evolve, embracing such technologies will be vital for manufacturers aiming to stay competitive in a rapidly changing market.

Future Trends in Global Supply Chains and Home Appliance Production

The landscape of global supply chains in the home appliance industry is poised for transformative changes driven by various trends. One significant trend is the move towards regional supply chains. As companies seek to mitigate risks associated with global disruptions, such as pandemics or geopolitical tensions, there is a growing emphasis on localizing production and sourcing materials. This strategy not only shortens lead times but also enhances flexibility and responsiveness to market demands. A focus on regional supply chains can result in a more resilient framework for home appliance manufacturers, allowing them to adapt to changing consumer preferences more effectively.

Additionally, technology plays a vital role in shaping the future of supply chains. The adoption of advanced technologies such as artificial intelligence, the Internet of Things (IoT), and blockchain is reshaping traditional business models. These technologies facilitate enhanced visibility along the supply chain, enabling manufacturers to better track inventory levels, forecast demand, and optimize logistics. For instance, AI-driven analytics can predict trends in consumer behavior, allowing companies to adapt their production strategies accordingly. This technological integration not only increases operational efficiency but also fosters innovation in product development, making it crucial for home appliance manufacturers to stay ahead of the curve.

Moreover, environmental regulations are gaining prominence, influencing supply chain decisions. As consumers and governments alike prioritize sustainability, manufacturers are being compelled to adopt greener practices. This shift may include selecting eco-friendly materials, minimizing waste, and improving energy efficiency in production processes. Companies that proactively align their operations with environmental standards may not only comply with regulations but also enhance their brand reputation, appealing to a more environmentally conscious consumer base.

In conclusion, the future trends in global supply chains for home appliance production suggest a significant shift towards regionalism, technology-driven business models, and a heightened focus on sustainability. These evolving factors are expected to reshape the industry, prompting manufacturers to innovate and adapt in an increasingly dynamic market environment.

Conclusion: Navigating the Global Supply Chain Landscape

Throughout this blog post, we have examined the multifaceted relationship between global supply chains and the production of home appliances. The complexities involved in sourcing materials, manufacturing processes, and distribution networks illustrate that the success of home appliance manufacturers heavily relies on their ability to effectively manage these intricate supply chains. This dependency highlights the necessity for organizations to cultivate robust relationships with suppliers, streamline logistics, and embrace technological advancements to enhance their operational efficiency.

As the global economy continues to evolve, manufacturers must remain vigilant to the shifting dynamics of supply chains. Disruptions caused by unforeseen circumstances, such as natural disasters or geopolitical tensions, can significantly affect production timelines and cost structures. Consequently, home appliance companies are encouraged to invest in strategies that foster resilience and flexibility. These strategies may involve diversifying their supplier base or incorporating advanced forecasting techniques to predict potential disruptions.

Moreover, innovation plays a substantial role in mitigating the risks prevalent within global supply chains. By adopting new technologies, such as automation and data analytics, manufacturers can improve their responsiveness to changing market demands and optimize their production processes. This not only enhances efficiency but also contributes to sustainable practices, which are increasingly important to consumers. As environmental considerations take center stage, companies must adapt to these expectations by integrating eco-friendly materials and processes into their supply chains.

In conclusion, navigating the global supply chain landscape is crucial for the success of home appliance production. By emphasizing adaptability and innovation, manufacturers can position themselves to not only survive but thrive in an ever-changing environment. The importance of understanding and managing global supply chains cannot be overstated, as it serves as the foundation for continued growth and competitiveness in the home appliance sector.