Automation has significantly transformed the landscape of home appliance production. Historically, the manufacturing of appliances relied heavily on manual labor, where workers performed labor-intensive tasks to assemble products. This traditional approach, although effective in its time, often resulted in slower production rates and variable quality output. With the rise of industrialization in the late 18th and 19th centuries, some mechanization began to take place, yet it was not until the latter half of the 20th century that more sophisticated automated technologies emerged.

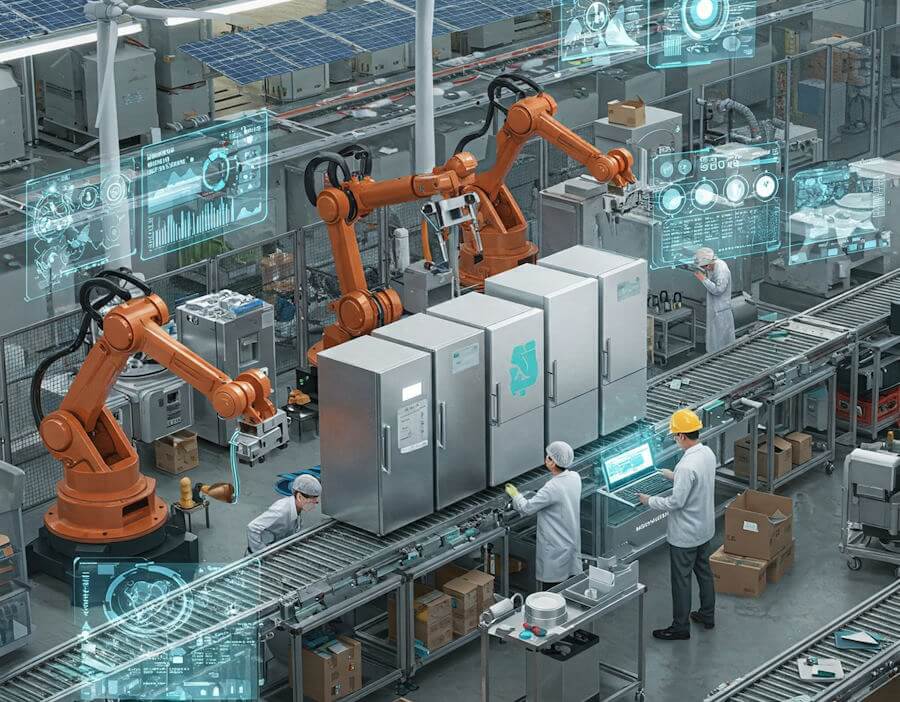

The gradual introduction of automation into the manufacturing process has been driven by advancements in technology. The incorporation of robotics, computer-aided design (CAD), and computer numerical control (CNC) machinery has facilitated precision in manufacturing, which was previously unattainable with manual methods. Today, robotics systems in appliance production effectively perform repetitive tasks, such as assembling parts, welding, and painting, thereby increasing both speed and consistency. Furthermore, automation has streamlined supply chain processes, allowing for just-in-time production methods that significantly reduce inventory costs.

In the current state of the industry, automation is not merely an option but a necessity for competitiveness. Manufacturers that have adopted automated systems report enhanced efficiency and improved product quality, leading to greater customer satisfaction. Moreover, automation helps mitigate labor shortages by fulfilling roles that require high levels of precision and repetition. As businesses continue to innovate, the integration of advanced technologies, such as artificial intelligence and machine learning, is poised to redefine the production landscape further.

The key benefits of implementing automation in home appliance production encompass increased operational efficiency, enhanced product quality, and reduced production costs. As the industry evolves, the role of automation will continue to expand, shaping the future trajectory of home appliance manufacturing.

Types of Automation Technologies Used

In the realm of home appliance production, various types of automation technologies play a pivotal role in enhancing efficiency and precision. One of the most prominent technologies employed is robotics. Industrial robots are widely used for tasks that require speed, accuracy, and consistency. These robots can perform a range of functions, from assembly line work to quality control inspections. Their ability to operate continuously, without fatigue, significantly enhances production output and minimizes errors. As a result, manufacturers can ensure that their appliances meet stringent quality standards while also reducing labor costs.

Another critical technology is computer numerical control (CNC) machines. CNC technology allows for the precise manipulation of tools and machinery based on computer-generated designs. In home appliance production, CNC machines are utilized for cutting, drilling, and shaping materials with remarkable accuracy. This precision in production not only facilitates the creation of intricate designs but also ensures that products fit together seamlessly, thereby improving both functionality and aesthetics. The integration of CNC machines into manufacturing processes has revolutionized the way components are produced, offering significant advantages in speed and consistency.

Conveyor systems also contribute to the automation landscape in appliance manufacturing. These systems streamline the movement of materials and finished products along the production line. By automating the transportation of components between stages of assembly, conveyor systems help in reducing manual handling and increasing overall workflow efficiency. Furthermore, they support just-in-time manufacturing, which minimizes inventory costs and optimizes space utilization within facilities.

Lastly, software systems for inventory and manufacturing processes are instrumental in managing production schedules and supply chain operations. These systems facilitate real-time tracking of resources, which subsequently enhances the decision-making capabilities of manufacturers. By automating inventory management, businesses can forecast needs more accurately and maintain optimal stock levels, thereby preventing production delays and excess inventory.

Economic Impact of Automation on Manufacturers

The integration of automation in the home appliance manufacturing sector presents a profound economic impact that can reshape production dynamics. One of the primary advantages of automation is cost reduction. By implementing advanced technologies such as robotics and machine learning, manufacturers can lower labor costs and minimize human error, which often leads to increased efficiency and significant savings in operational expenses. These reductions allow companies to allocate resources more effectively, thus enhancing their overall financial performance.

Furthermore, automation typically yields a favorable return on investment (ROI). While the initial costs associated with acquiring automated systems can be substantial, the long-term benefits frequently outweigh the expenses. Increased productivity means that manufacturers can produce more units in less time, resulting in heightened output and, consequently, higher revenue. This cycle of investment and return fosters a sustainable economic model for many businesses in the sector.

As automation technology advances, shifts in labor needs become evident. While some jobs may become obsolete due to mechanization, there is also a growing demand for skilled labor to maintain and operate sophisticated automated systems. This transition requires a strategic approach to workforce management, emphasizing upskilling and reskilling initiatives to prepare existing employees for new roles in an automated environment. As a result, manufacturers not only face the challenge of adapting to these changes but also have the opportunity to create a more skilled workforce that can add significant value to production processes.

The competitive advantages gained through automation are manifold. Businesses that adopt these technologies often witness improved product quality, quicker turnaround times, and the ability to meet rapidly changing consumer demands more efficiently. However, manufacturers should also remain aware of potential risks, such as cybersecurity vulnerabilities and the high costs of system maintenance. Balancing these factors is crucial as companies navigate the complex landscape of automation in home appliance production.

Effects on Employment in the Home Appliance Sector

The introduction of automation in the home appliance production sector significantly alters the landscape of employment. As companies increasingly adopt advanced robotics and artificial intelligence, traditional labor roles are wittingly or unwittingly displaced. These automated systems are designed to enhance efficiency, speed up production processes, and reduce operational costs, leading to a diminished reliance on manual labor. This shift raises concerns regarding job security for workers whose skills may no longer be in demand.

However, while automation may lead to a reduction in certain roles, it concurrently creates new opportunities within the home appliance industry. The emergence of advanced technologies necessitates a qualified workforce equipped with technical skills to manage, maintain, and develop these automated systems. In this context, many companies find themselves on the lookout for specialists in robotics, data analysis, and systems engineering. Consequently, job roles evolve, and the focus shifts from traditional roles towards more technical positions, fostering an essential transformation in the workforce.

Moreover, the rapid pace of technological advancement highlights the critical need for workforce reskilling and upskilling. As conventional jobs decline, current employees must adapt to new roles that incorporate automation technologies. Educational institutions and companies increasingly collaborate to provide training programs aimed at equipping workers with the necessary skills to operate in an automated environment. Such initiatives not only benefit the employees by enhancing their employability but also assist companies in maintaining a skilled labor pool capable of harnessing the power of automation.

In this evolving landscape, it is essential to strike a balance between the negative impacts of job displacement and the positive effects of job creation through automation. The challenge lies in ensuring that workers are supported throughout this transition, highlighting the importance of proactive measures in facilitating a smooth adaptation to the new realities of the home appliance production sector.

Quality Control Improvements through Automation

Automation has revolutionized the quality control processes within the home appliance production industry, leading to significant enhancements in consistency and efficiency. As manufacturers increasingly adopt automated inspection systems, the capacity to detect defects and variations throughout the production line has drastically improved. Unlike traditional manual inspections, automated systems utilize advanced technologies such as machine learning and artificial intelligence to analyze products with precision. This allows for real-time monitoring of production quality, enabling immediate interventions when anomalies are detected.

For instance, automated visual inspection systems are capable of identifying flaws that human inspectors may overlook, including minor blemishes or misalignments. These systems employ high-resolution cameras and complex algorithms to analyze every unit, ensuring that only products that meet predetermined quality standards move forward in the production process. This reduces the number of defective appliances reaching consumers, thereby enhancing overall customer satisfaction and trust in the brand.

Furthermore, the integration of data analytics in quality control processes has significantly augmented the effectiveness of automation. By collecting and analyzing vast amounts of data generated during production, manufacturers can identify patterns and trends that might indicate potential quality issues. This predictive analysis informs decision-making, allowing producers to implement preemptive measures before defects occur. Consequently, the manufacturing process becomes not only more efficient but also profoundly more reliable, minimizing waste and lowering costs associated with returns and repairs.

In essence, the advent of automation in quality control has established a more robust framework for maintaining high production standards in home appliances. The enhanced capability to consistently detect defects, combined with the power of data analytics, empowers manufacturers to optimize their processes, ultimately leading to superior product quality and elevated customer satisfaction.

Sustainability and Environmental Considerations

The integration of automation in home appliance production represents a significant evolution towards more sustainable manufacturing practices. One of the primary benefits of automated processes is their capacity to reduce energy consumption during production. By employing advanced robotics and automated machinery, manufacturers can optimize the production workflow, thereby minimizing the energy required to assemble each appliance. This shift not only lowers operational costs but also contributes to a decrease in the overall carbon footprint associated with the manufacturing process.

Moreover, automation facilitates the implementation of precise manufacturing techniques, leading to a notable reduction in material waste. Traditional production methods often generate substantial amounts of scrap and byproducts. In contrast, automated systems can enhance manufacturing accuracy, ensuring that materials are utilized more efficiently. This precision aligns with sustainable production goals and helps manufacturers meet regulatory requirements concerning waste management and recycling.

The role of automation extends beyond the production process itself; it also influences the development of energy-efficient appliances. With the advancement of intelligent technologies, manufacturers can create appliances designed for optimal energy performance. Automation enables the integration of smart features that allow appliances to adapt their functionality based on user behavior and environmental conditions, further promoting energy savings during the product’s operational life.

In light of these factors, it is evident that the incorporation of automation in home appliance production presents a viable pathway toward enhancing sustainability efforts. By focusing on reducing energy consumption, minimizing waste, and developing energy-efficient products, the manufacturing sector can significantly contribute to environmental preservation. Therefore, as the automation trend continues to grow, its impact on sustainability in home appliance production will become increasingly pronounced and essential to the industry’s future.

Consumer Perspectives on Automated Appliances

The rise of automation has significantly reshaped consumer attitudes towards home appliances. As modern technology continues to evolve, automated appliances, including smart refrigerators, washing machines, and vacuums, have become increasingly integrated into daily life. Consumers between demographics are generally intrigued by the convenience and efficiency that these automated options provide. However, their perceptions of quality, reliability, and safety diverge on several fronts.

Many consumers appreciate the advanced features of automated appliances, favoring their ability to streamline household tasks and enhance productivity. For instance, smart appliances often come equipped with Wi-Fi connectivity that allows users to control them remotely via mobile applications. This technology can lead to energy savings, as consumers can monitor usage and receive notifications about maintenance needs or malfunctions. Such aspects bolster consumer confidence in automated models as viable alternatives to traditional appliances.

Despite the appeal of automation, concerns about quality and reliability persist within the consumer base. Some individuals question whether automated appliances can perform as effectively as their traditional counterparts. Specific issues, such as the longevity of smart devices or their potential for software glitches, are of particular concern. Furthermore, the integration of technology introduces a perceived complexity that can make some consumers hesitant to embrace these advancements fully.

Another notable trend is the growing emphasis on safety. Consumers often seek assurances that automated appliances meet rigorous safety standards to prevent accidents typically associated with electronic devices. Brands that prioritize transparency in their manufacturing processes and adhere strictly to safety guidelines can gain a significant advantage in the marketplace. Ultimately, the overall perception of automated appliances is shaped by a balance of excitement for innovation and caution regarding reliability and safety, as consumers continue to navigate their choices in an increasingly tech-driven environment.

Future Trends in Automation for Home Appliances

The home appliance industry is on the brink of significant transformation, driven largely by advancements in automation. Emerging technologies such as artificial intelligence (AI) and machine learning are becoming integral to production processes, enabling manufacturers to enhance efficiency, reduce production costs, and improve product quality. The integration of these technologies not only streamlines operations but also allows for greater customization in appliance design, catering to the evolving needs of consumers.

As manufacturers adopt AI-driven automation, we can expect an increase in predictive maintenance capabilities. This involves using machine learning algorithms to analyze operational data and foresee potential malfunctions in appliances, thereby minimizing downtime and maintenance costs. Moreover, AI can facilitate smarter inventory management, ensuring that production lines operate at optimal capacity without overstocking or understocking materials.

Additionally, robotics is likely to play a key role in shaping the future of home appliance production. Collaborative robots, or cobots, will increasingly work alongside human operators, enhancing productivity and safety. These robots can perform repetitive tasks with precision, allowing skilled workers to focus on more complex and creative aspects of design and assembly. Such a synergy between human expertise and robotic efficiency can lead to better innovation and quicker product time-to-market.

Consumer adoption rates of automated home appliances are expected to rise as well. With growing awareness of smart home technologies, consumers are increasingly inclined to invest in appliances that offer automation features. This trend is not just limited to high-end products; even mid-range appliances are being equipped with smart functionalities, making them more accessible to a broader customer base. Overall, the future of automation in home appliance production appears bright, with continuous advancements promising significant impact across the industry.

Conclusion: The Future of Home Appliance Production

The evolution of home appliance production has significantly shifted with the advent of automation. By streamlining processes and enhancing efficiency, automation technologies have transformed the landscape, enabling manufacturers to produce appliances at a faster pace and with greater precision. The integration of robotics and artificial intelligence has not only reduced manufacturing costs but has also improved product quality, as machines can achieve consistency beyond human capabilities. This trend reflects a broader move towards smart manufacturing that embraces digital technologies and data analytics to optimize production lines continuously.

However, this transition does come with its set of challenges. As automation becomes more prevalent, there is a growing concern regarding job displacement within the industry. The reliance on machines raises questions about workforce adaptation and the need for retraining. Manufacturers must navigate these complexities while maintaining a commitment to innovation and sustainability. Balancing technology with human labor is essential to harness the full potential of automated systems without compromising job security.

Looking forward, the future of home appliance production is poised for continuous evolution. The increasing demand for smart home technologies and eco-friendly appliances signals an upward trajectory towards integrating more intelligent automation solutions. As producers aim to meet consumer expectations for convenience and energy efficiency, automation will play a pivotal role in shaping product development and manufacturing techniques. The industry must, therefore, remain agile, embracing both the advantages and the obstacles that automation presents. This nuanced understanding will be crucial for stakeholders aiming to thrive in an increasingly automated world.