Sustainable manufacturing refers to the creation of products through economically-sound processes that minimize negative environmental impacts while conserving energy and natural resources. This concept is gaining increasing relevance in modern industries, driven by a combination of environmental concerns, technological advancements, and shifting consumer preferences. Unlike traditional manufacturing methods, which often prioritize production volume and cost-effectiveness, sustainable manufacturing emphasizes the importance of reducing waste, lowering emissions, and utilizing renewable resources.

The importance of sustainable manufacturing cannot be overstated. As global awareness of climate change and environmental degradation rises, both consumers and regulatory bodies are demanding more responsible practices from manufacturers. In response, many companies are adopting eco-friendly approaches that not only meet these demands but also present opportunities for innovation and competitive advantage. The transition to sustainable manufacturing involves integrating sustainability into product design, production processes, supply chain management, and end-of-life product considerations.

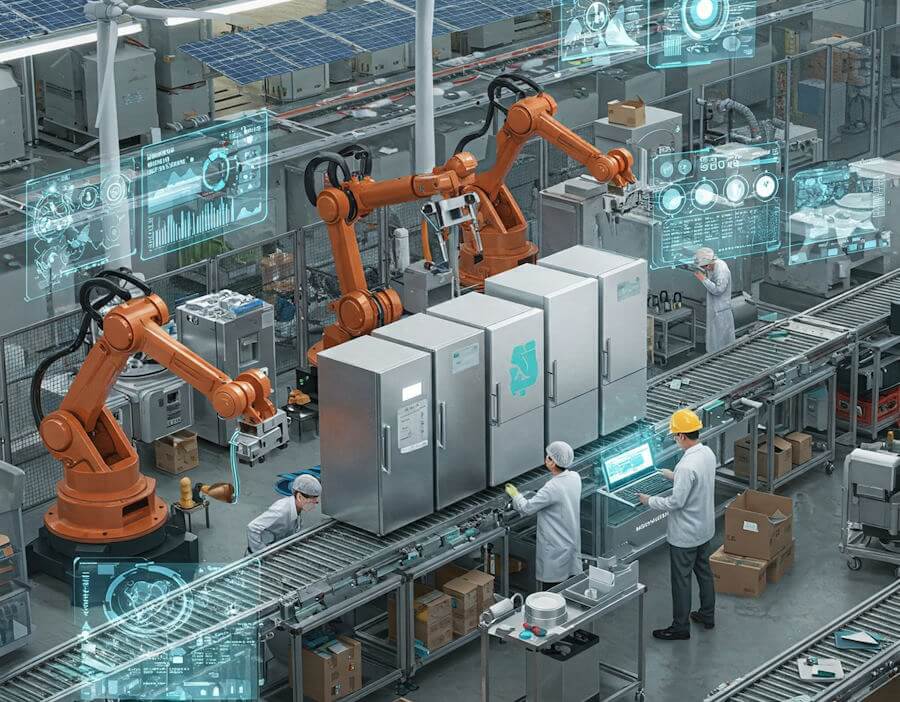

Furthermore, the shift towards sustainable practices is supported by advancements in technology that facilitate efficient resource use and waste management. For instance, the incorporation of smart manufacturing technologies, such as automation and data analytics, allows companies to optimize their production processes, reducing energy consumption and minimizing environmental footprints. As manufacturers recognize the value of sustainable practices, they are increasingly investing in green initiatives, ranging from eco-friendly materials to energy-efficient machinery.

This evolution in manufacturing methods is crucial not just for the planet but also for the long-term viability of businesses in an increasingly eco-conscious market. As consumer preferences tilt toward sustainability, companies that adopt these practices can enhance brand loyalty while contributing to a more sustainable future.

The Impact of Climate Change on the Home Appliance Industry

Climate change has emerged as a critical factor influencing various industries, including home appliances. The acute shifts in weather patterns, rising global temperatures, and unpredictable climatic events compel manufacturers to reassess their production methodologies and strategies. The home appliance industry faces significant challenges due to its substantial contributions to greenhouse gas emissions and resource depletion. With the increasing awareness of environmental sustainability, manufacturers are prompted to seek solutions that mitigate their ecological footprint.

One of the primary issues is the resource extraction associated with the production of appliances. The mining and processing of metals, plastics, and other materials used in home appliances often lead to environmental degradation, including habitat destruction and pollution. As the industry acknowledges its role in exacerbating climate change, there is a growing trend towards sourcing materials sustainably. Companies are now focusing on using recycled or rapidly renewable materials, thereby reducing their dependency on virgin resources and minimizing environmental harm.

Energy consumption during the manufacturing process is another area of concern. Traditional production techniques consume vast amounts of energy and often rely on fossil fuels, contributing further to climate change. Manufacturers are exploring innovative energy-efficient techniques and integrating renewable energy sources into their operations. This shift not only reduces emissions but also enhances cost-effectiveness by lowering energy expenses over time.

Furthermore, the generation of waste, particularly at the end of product life, poses a significant environmental challenge. Many appliances are not designed for easy disassembly or recycling, leading to increased landfill contributions and wasted resources. Responding to this issue, the industry is beginning to adopt design for sustainability principles. This allows for easier recycling and reusability of components, thus promoting a circular economy.

In conclusion, the impact of climate change on the home appliance industry is prompting a crucial transformation. By implementing sustainable practices, manufacturers are not only reducing their environmental impact but are also aligning with consumer expectations for eco-friendly products.

Key Trends in Sustainable Manufacturing Practices

Sustainable manufacturing has emerged as a pivotal force in transforming the home appliance industry. One of the most significant trends is the increasing use of renewable materials. Manufacturers are now prioritizing sustainable resources such as bamboo, recycled plastics, and biodegradable materials. These materials not only reduce the carbon footprint associated with production but also encourage responsible consumption among consumers. By incorporating renewable resources into their designs, companies are effectively contributing to a more sustainable cycle of production and consumption.

In addition to renewable materials, energy-efficient designs are gaining prominence in the sector. Home appliances now undergo rigorous assessments to optimize their energy consumption throughout their lifespan. Innovations such as smart technology enable devices to operate more efficiently, reducing energy usage and decreasing household energy costs. For instance, appliances equipped with IoT (Internet of Things) capabilities can adjust their operation times based on the energy demand of households, thus improving overall efficiency. This trend aligns with global efforts to curb energy reliance on fossil fuels, thereby supporting a wider initiative for sustainable living.

Furthermore, the implementation of circular economy principles is rapidly reshaping manufacturing practices within the home appliance industry. Companies are focusing on the entire lifecycle of their products—from design to post-consumer waste management. This approach aims to minimize waste through strategies such as product refurbishment, recycling, and upcycling. By designing appliances for longevity and ease of disassembly, manufacturers facilitate repairability and recycling, ensuring that materials remain in use for as long as possible.

In conclusion, the home appliance industry is witnessing key trends that prioritize sustainability. Through the integration of renewable materials, energy-efficient designs, and circular economy practices, manufacturers are paving the way for a more sustainable future, benefitting both consumers and the environment.

Technological Innovations Driving Sustainability

Technological advancements are at the forefront of transforming the home appliance industry toward more sustainable manufacturing practices. Smart manufacturing, often characterized by the integration of the Internet of Things (IoT), plays a pivotal role in this evolution. IoT devices facilitate real-time data collection and analysis, enabling manufacturers to optimize production processes efficiently. These technologies allow for a more agile response to supply chain fluctuations and demand variations, ultimately reducing waste and resource consumption.

Moreover, automation technologies contribute significantly to sustainable manufacturing by streamlining operations and minimizing human error. Automated systems can perform repetitive tasks with precision, enhancing productivity and reducing energy usage. For instance, robotic process automation (RPA) allows for the efficient assembly of appliances with reduced energy input compared to traditional methods. This leap towards automation not only improves production speed but also optimizes the use of materials, leading to less scrapped product and waste.

Additionally, advances in sustainable materials science are being integrated into manufacturing processes. For example, the development of eco-friendly alternatives to traditional plastics enables manufacturers to produce appliances that are not only durable but also recyclable at the end of their lifecycle. This innovation reduces the dependency on fossil fuels and contributes to a circular economy approach in the industry.

In the context of energy consumption, smart technologies allow for enhanced energy management within manufacturing facilities. Smart grids, coupled with renewable energy sources, can power production lines more sustainably, decreasing reliance on non-renewable energy forms. This integration of green technologies into the manufacturing processes is essential for reducing the carbon footprint associated with home appliances.

As the industry continues to innovate, the role of technological advancements will be crucial in laying the groundwork for a more sustainable manufacturing landscape, significantly benefiting both the environment and the economy.

Case Studies of Sustainable Home Appliance Brands

The evolution of sustainability in the home appliance industry has birthed several pioneering brands that embody eco-consciousness through their product innovations and business practices. One prominent example is Samsung. The company has made significant strides toward reducing its environmental footprint by implementing energy-efficient technologies that minimize electricity consumption. Their Ultra Energy Efficient washing machines, for instance, utilize advanced sensors that adjust water usage based on the load, promoting water conservation while maintaining optimal performance.

Another leader in sustainable manufacturing is Bosch. Bosch’s commitment to sustainability shines through its energy-efficient dishwashers, which are designed with the planet in mind. With features such as eco-silence drive motors and sensor-controlled load sensing, these dishwashers not only reduce energy and water usage but also enhance user convenience. Bosch has positioned itself as a frontrunner in sustainable appliance innovation, demonstrating that eco-friendly practices can coexist with high-quality product designs.

A further noteworthy example is GE Appliances, which has embraced sustainable practices across its product line. They have introduced the GE Profile™ Series, featuring appliances made with recyclable materials and equipped with smart technology that optimizes energy consumption. The company’s use of sustainable packaging has also decreased landfill waste significantly. GE Appliances has succeeded in aligning its operational strategies with sustainability goals, actively reducing greenhouse gas emissions and pledging to achieve carbon neutrality across its operations.

These case studies illustrate tangible applications of sustainable practices within the home appliance sector, showcasing how innovative design, efficient technologies, and responsible manufacturing can lead not only to environmental benefits but also to enhanced consumer satisfaction. As these brands continue to set benchmarks in sustainability, they pave the way for future developments in the home appliance industry, proving that profitability and environmental stewardship can indeed go hand in hand.

Challenges Faced by Manufacturers in Adopting Sustainable Practices

The transition to sustainable manufacturing in the home appliance industry is fraught with several significant challenges. One of the most pressing barriers is economic constraints. Implementing sustainable practices often requires substantial upfront investment. For many manufacturers, the costs associated with upgrading technology and processes to reduce environmental impact can be prohibitively high. These investments, while beneficial in the long term, may deter smaller companies from fully committing to sustainable initiatives.

Another challenge is consumer perception. Although there is a growing awareness of environmental issues, many consumers remain hesitant to pay a premium for sustainably produced home appliances. This reluctance can result from a lack of understanding of the long-term benefits of such products or the belief that performance may be compromised by more sustainable alternatives. Consequently, manufacturers may find it difficult to balance profitability with their sustainability goals, as they navigate the fine line between consumer demand and ethical responsibility.

Additionally, supply chain issues present significant obstacles. The sourcing of sustainable materials can often be more complex and costly than traditional methods. Manufacturers must not only vet suppliers for their commitment to sustainability but also ensure that the entire supply chain adheres to environmentally friendly practices. This comprehensive approach to sustainability can be complicated by logistics challenges and varying regulations across different regions.

Finally, the need for skilled labor cannot be overlooked. Transitioning to more sustainable practices requires employees who are trained in new technologies and methodologies. The availability of such skilled labor is limited, and manufacturers may struggle to recruit or retain personnel with the necessary expertise in sustainability practices. Together, these challenges create a multifaceted barrier to the widespread adoption of sustainable manufacturing in the home appliance sector.

The Role of Government and Regulations in Promoting Sustainability

Government policies and regulations play a crucial role in shaping the landscape of sustainable manufacturing within the home appliance industry. Through a variety of initiatives and incentives, governments worldwide are encouraging manufacturers to adopt eco-friendly practices. One significant approach is the implementation of strict energy efficiency standards that appliances must meet before they can be sold in the market. These regulations not only encourage manufacturers to innovate but also empower consumers to make environmentally conscious decisions when purchasing home appliances.

In addition to energy efficiency requirements, governments are increasingly offering tax incentives and grants to companies that invest in sustainable manufacturing processes. These financial benefits can significantly ease the transition for manufacturers aiming to reduce waste and lower their carbon footprint. Moreover, regulations surrounding the use of hazardous materials, such as lead and mercury, have been established to ensure that home appliances are safer for both the environment and consumers. These actions are aligned with broader national and international objectives aimed at combating climate change.

Certifications play an essential role in the sustainable manufacturing landscape, providing a framework for evaluating and validating eco-friendly practices. Programs such as ENERGY STAR in the United States or the EU Energy Label in Europe serve as benchmarks for manufacturers striving for sustainability. These labels enhance consumer awareness and drive market demand for energy-efficient appliances, ultimately leading to a healthier environment. By promoting such certifications, governments can catalyze a shift towards sustainable practices across the industry.

On an international level, agreements like the Paris Accord set ambitious targets for reducing greenhouse gas emissions, further motivating countries to implement stringent regulations for the home appliance sector. These commitments signal to manufacturers that sustainability is a priority, fostering collaboration among nations in the pursuit of eco-friendly innovations. As the home appliance industry continues to evolve, the protective role of government and regulations remains pivotal in steering the sector toward a sustainable future.

Consumer Expectations and Market Demand for Sustainable Appliances

In recent years, consumer expectations regarding sustainability have undergone a significant transformation, particularly in the home appliance industry. As awareness of environmental issues grows, customers increasingly seek out eco-friendly products that minimize their carbon footprint and promote responsible consumption. This shift in consumer behavior is driven by a combination of factors, including increased access to information, the influence of social media, and evolving values among younger generations.

Market trends indicate a clear preference for sustainable home appliances, reflecting a wider societal shift towards sustainability. Research suggests that consumers are willing to pay a premium for products that promise energy efficiency and eco-friendly features. The Energy Star rating, for example, has become a sought-after label for appliances that meet stringent efficiency criteria. Additionally, the rise of various certifications and eco-labels influences purchasing decisions, as consumers feel more informed and confident about the choices they make.

To effectively respond to these demands while remaining competitive, manufacturers must innovate and adapt. This includes investing in more sustainable materials, enhancing the energy efficiency of appliances, and implementing better end-of-life disposal programs. Furthermore, companies can capitalize on consumer interest by emphasizing transparency in their supply chains, showcasing eco-friendly practices, and engaging in storytelling that resonates with environmentally conscious buyers.

The integration of sustainable practices not only aligns companies with consumer values but also sets them apart in a crowded market. By prioritizing sustainability, manufacturers can enhance brand loyalty and appeal to a growing demographic that prioritizes both functionality and ecological responsibility in their purchasing decisions. As this trend continues to evolve, it will undoubtedly reshape the landscape of the home appliance industry.

Future Outlook: Sustainable Manufacturing in Home Appliances

The home appliance industry is undergoing a significant transformation toward sustainable manufacturing, driven by and aligned with growing consumer awareness and demand for environmentally friendly products. As we look to the future, several emerging trends are poised to reshape this sector. First and foremost, advancements in technology will facilitate the integration of sustainable practices across manufacturing processes. Innovations such as artificial intelligence and the Internet of Things (IoT) are leading to more efficient energy use, optimizing supply chains, and reducing waste. This increased efficiency is critical as manufacturers strive to minimize their carbon footprints.

Moreover, the adoption of circular economy principles is likely to gain momentum. Rather than following a traditional linear model, where products are produced, used, and then discarded, the circular economy promotes recycling, reusing materials, and minimizing waste. Manufacturers that pivot to this approach can create appliances designed for disassembly, allowing for easier repair and recycling at the end of their lifecycle. This shift not only improves sustainability but can also enhance brand loyalty as consumers increasingly prefer companies that demonstrate environmental responsibility.

Staying adaptable to changes in consumer behavior will be essential for companies aiming to thrive in this evolving marketplace. As eco-consciousness grows, there is an increasing emphasis on the transparency of supply chains and sourcing of sustainable materials. Brands must communicate their sustainability efforts effectively to connect with their target audiences and maintain relevance. Additionally, as environmental policies continue to evolve and tighten, businesses need to remain proactive in complying with regulations and anticipating future changes.

The home appliance industry is at a critical juncture. The commitment to sustainable manufacturing not only offers a competitive advantage but is also essential for the long-term viability of the industry. As the future unfolds, innovation, adaptability, and consumer engagement will be the pillars supporting the transition towards a more sustainable market.